Digital Innovation Gazette: Tech Trends

Green Means GO! The Technology Behind the World Solar Challenge

By Brian Taylor for Digital Innovation Gazette

The World Solar Challenge is a 3,000 kilometer race across the Australian outback. That’s 3,000 kilometers of scrubland and blistering sunlight — the kind of environment that’s not particularly welcoming to humans or technology, unless that technology happens to be solar-powered.

In late October 2011, for the eleventh race since 1987, a group of solar-powered cars designed by groups from around the world attempted to cross the continent, from Darwin to Adelaide, on solar power alone. Some cars made it; some had to resort to being towed on trailers part of the way by gasoline-powered vehicles. Members of one 70-person-strong team from Cambridge University designed, built and drove a car in the race.

The Start of a Racing Team

The Cambridge University Eco Racing (CUER) team first competed in the 2009 World Solar Challenge. CUER, founded four years ago, has its roots in another Cambridge: In 2007, an engineering student named Martin McBrien spent a year studying at MIT in Cambridge, Mass. While in the U.S., McBrien was inspired by a project there working to create and race solar-powered cars. Upon his return to the U.K., McBrien founded the CUER team, recruiting students who used a solar cell they acquired from MIT to build a prototype solar car, which they christened Affinity.

“The year after that, the original CUER team was able to raise money and go on an end-to-end trip across the U.K., from one tip to the other tip: John O’Groats to Land’s End,” says Mark Nicholson, CUER’s current business manager, leader of both the sponsorship and PR teams, and a chemistry student at Cambridge. “They enlisted schools and various public places along the way to advertise the project.” The Affinity was the first solar car to cross the U.K. on solar power alone.

CUER’s next car was the Endeavour, which they raced in 2009. Despite a battery issue, the team managed to place 14th out of a field of 26 in their first transcontinental race. Returning home, they were excited to continue working on the car, preparing it for the next race in 2011. The students faced a mix of challenges: developing sustainable energy and automotive technology, promoting education outreach and acquiring sponsorship.

Securing the Funding

Sponsorships were key to CUER’s next (and current) car, the Endeavour Mk II. “The majority of our funding comes from sponsors,” says Nicholson. “We get some from the engineering department, mostly in the form of help: A large number of things are set up for the faculty researchers to use, and we get the ability to use quite a lot of those. Room bookings, hiring cars, printing — the kind of day-to-day stuff you need. They’re quite helpful, but there’s a limit to what the university can do.”

The fall of 2009 wasn’t the best time to be looking for sponsors for something as seemingly off-the-wall as solar car racing. But early in 2010, the team had a little bit of luck: They met Mark Green, a technical marketing engineer for Intel. [Disclosure: Intel’s Visual Adrenaline magazine is the sponsor of DigitalInnovationGazette.com.]

“The relationship came out of a chance meeting. I went to a local school’s Transport Day with my family back in March 2010,” says Green. “The CUER team had a stand with their car. I noticed that there were several corporate logos on it. I was very interested in what they were doing and got to talking to them, exploring whether there was an opportunity for sponsorship from Intel.”

There was a precedent: Green and Intel sponsor the Bloodhound SSC Engineering Adventure, a project in which engineers design a car that can reach speeds of 1,000 miles per hour. Green knew that sponsoring CUER would provide a blend of opportunities in engineering and educational outreach, as well as offering computer equipment and some technical support. The Bloodhound Adventure, though focused on land speed records rather than solar power, had similar goals to CUER: to develop new technologies under extreme automotive conditions that could lead to useful breakthroughs for everyday people, while also motivating young people to get involved with science, technology, engineering and mathematics.

Assembling the Team

Since the CUER team is made up of university students, the project provides double educational benefits: It actively trains future engineers and engages younger students through demonstrations and community outreach. “We ran a competition for schools last year and invited the finalists up to Cambridge for a Solar Fun Day,” says Nicholson. “The competition was aimed at 6- to 13-year-olds.”

CUER is a key part of the education for many of the students involved in the project, according to Nicholson. The engineering program at Cambridge requires students to work on a project for a year. But for some dedicated students, working with CUER is a four-year commitment. “We’ve got some people who joined in their first year and have now graduated having just been to Australia,” says Nicholson. “So they’ve been following the project the entire way through.”

Some of those recently graduated students are still involved in the project in an advisory capacity, explains Nicholson. And even with those members’ recent graduation, the team is still fairly large. “We’ve got about 20 in the business team (sponsorship and PR) and more like 40 in the technical team,” says Nicholson. “And then there’s the senior team, a group of five or six of us who are much more heavily involved in the project.

Building the Car

The technical team works the most with sponsor-provided tools, including workstations with solid-state drives (SSDs), a micro-processor and an SSD for in-car telemetry, consulting support, and access to a high-performance computing cluster located in Swindon, a city about 150 miles southwest of Cambridge. The team uses this HPC center to run its computational fluid dynamics simulations.

According to CUER, this cluster allows them to run in six minutes a simulation that took 24 hours to run during their 2009 preparation. Speeding up simulation also means speeding up the design process: After running a simulation, the team is able to quickly and easily make changes to their model and run it again. This means that developments that once took eight weeks can now be achieved in one afternoon.

Under the Hood

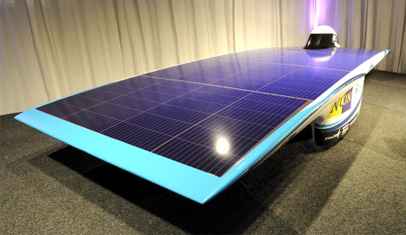

The three-wheeled Endeavour looks like a large diving board — or a giant white tongue — covered with black rectangles (the solar cells), with a cockpit for the driver rising out of the back section. Support vehicles, which accompany the Endeavor on its races across the outback, have computers that communicate with onboard telemetry systems in the car. This communication system allows members of the team to monitor the car’s power supply, speed and other stats, without the need for the driver to relay them verbally.

The system generates nearly 2 GB of data every day, which is stored on the SSD in the system. Unlike a standard hard disk drive, the SSD has no moving parts and isn’t affected by the Endeavour’s lack of smooth suspension. (Shocks would weigh the car down too much.)

The 2011 Challenge

The sun did not shine upon much of the October 2011 race: Smoke from brushfires and heavy clouds prevented the vehicles from completing the race on solar power, and the vehicles had to be towed on a trailer for parts of the race. Despite nature being against them, the CUER team managed to log nearly 1,500 solar kilometers — almost half of the height of the Australian continent traversed on solar power — and finished 25th out of 37 teams.

The team’s experiences will help members in the future, whether they’re returning to the team for another year, or have graduated and are moving on to obtain their doctorates or pursuing careers in engineering. And as the project continues, it will keep training students to work in a world where sustainable technology is important and where engineering is engaged with the public through education.

Photo Credit: Getty Images

Brian Taylor has written for Kill

Screen, Paste, Edge and the Pittsburgh

City Paper, among others. He is a freelance librarian, writer and photographer

from Pittsburgh, Penn.